Last Updated on 25/11/2022

What is hydrophobic down? In this guide, you will learn what hydrophobic down is, how it is made, what the benefits are as well as the disadvantages. We also share a better way to keep down insulation dry as an alternative to treated down…

When looking for a new down jacket or down sleeping bag, you may have seen the term ‘hydrophobic down’ being thrown around a bunch. But what does this actually mean? Do you even need hydrophobic down fill? And is hydrophobically treated down worth the money? That is what we are here to share.

What is Hydrophobic Down?

Hydrophobic down is goose or duck down that has been treated with a water-repelling chemical to make it less vulnerable to moisture.

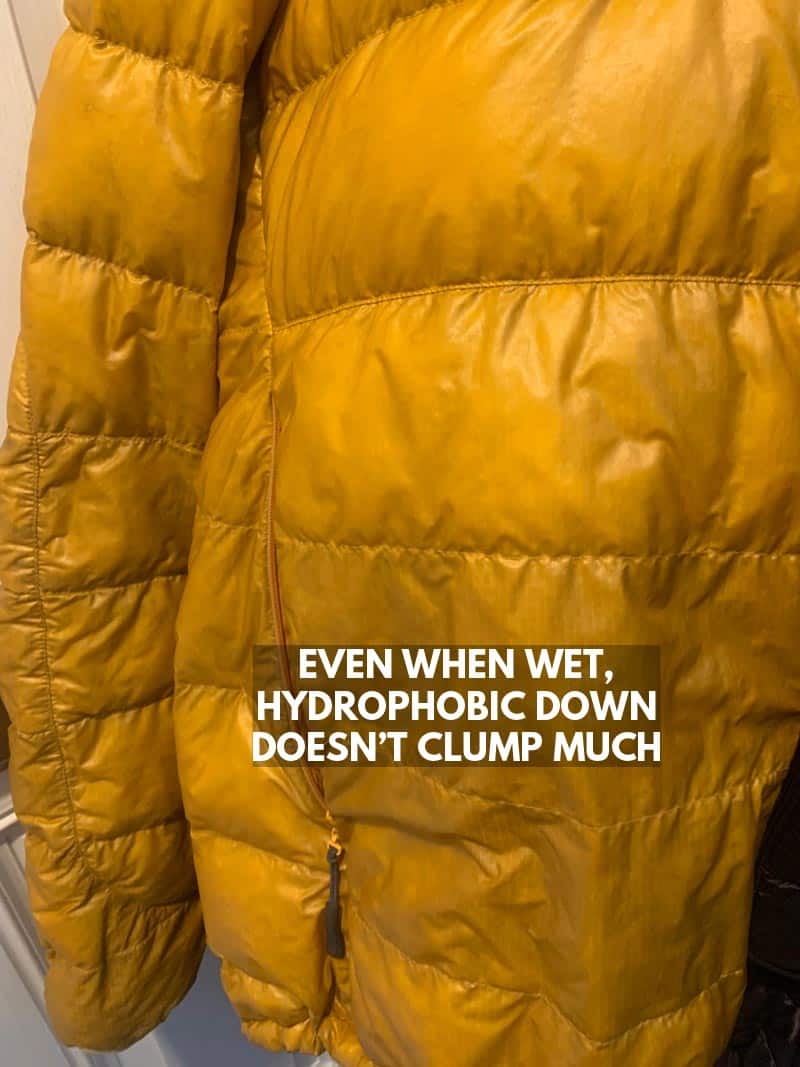

Down is naturally hydrophobic but once it is turned into insulation for clothing or sleeping bags it is susceptible to clumping if it gets wet. Clumping is bad. It’s when all the feathers stick together and absorb water which drastically reduces downs insulative properties. Here is our guide on how to reverse down clumping if it happens.

Hydrophobically treated down absorbs less water than untreated down and so will not clump as easily when wet. This allows the treated down to retain loft and insulation for longer so that you will stay warmer even if you get wet. Down with a DWR treatment also has the benefit of drying out much faster which has its advantages when you are living in it for days on end.

5 Main Benefits of Hydrophobic Down

-

- Absorbs up to 90% less water

- Dries up to 17 times faster

- Keeps you warm when wet

- Less clumping when wet

- Can sustain more exposure to moisture for longer

One of the main benefits of hydrophobic down is that it is less vulnerable to becoming soaked and unusable in sustained wet conditions. This is especially important for down jackets if wearing them in the rain. Perhaps more important for backpackers though is the ability to dry out so much faster.

Hydrophobic down has been shown to absorb up to 90% less water and dry up to 17 times faster than untreated down when soaked. This is a massive advantage for people who are using their down jackets or sleeping pads every day and don’t have the luxury of a dryer. If for example, you are on a thru-hike and have to pack your wet gear away before it has a chance to dry out the hydrophobic down is a game changer.

If for any reason your hydrophobic down gets wet, it will continue working far longer than untreated down. The performance will be reduced but you will at least be able to stay warm. Hydrophobic down is the more reliable choice if there is a chance you may get wet.

3 Main Downsides of Hydrophobic Down

-

- Sacrifices some of the loft

- Lower warmth-to-weight ratio

- More clumping when dry

All of the downsides of hydrophobic down I could think of revolve around how the chemical coating can marginally decrease the down’s natural properties such as lofting. While it may be noticeable at first, I believe that over time a treated down loses its loft faster than an untreated down. It may also have less loft from the start but we haven’t tested this at Gear Assistant yet.

So by adding a chemical to the down it may lose some initial loft when dry but this can lead to clumping which in turn affects the loft even more. The chemical treatment is often applied at the source so that it can dry out completely before being used in some outdoor gear or clothing.

The reduced loft and the subtle addition of dried chemicals to any hydrophobic down will lower its effective warmth-to-weight ratio. Meaning that it may take more hydrophobic down to achieve the same level of warmth as natural untreated down.

Treated Vs Untreated Down

The best way to decide between treated and untreated down is to think about when, where, and how you will be using your down garment. The idea is that you should only seek out hydrophobic down if you plan to use your product in circumstances beyond the limits of natural down. Here are some examples of when you might want to pick one or the other:

When You Should Choose Treated Down

Here are some examples of times when you should use hydrophobic down:

- If you wear your down jacket as your outer layer in all weather

- If you wear your down jacket for multiple days without having a chance to fully dry out

- When your life could be in danger – if the down gets wet with no way to dry it

- Notoriously wet conditions like on a boat – in fact in this case, I would insist you choose synthetic insulation instead

- When it is your thru-hiking sleeping bag which often gets packed away damp before it has fully dried out

One scenario where hydrophobic down always comes in handy is on a multi-day camping trip when you don’t have the opportunity or facility to dry your down filled gear out. Maybe you have to get up every morning and pack away your damp sleeping bag only to get back into it wet 16 hours later. Or maybe you are in a cold location and need to wear your down jacket all the time, if it gets wet you could be in trouble.

If you are exploring remote locations where the weather can turn bad with very little warning then your life may depend on your ability to stay warm. Hydrophobic down is like having an insurance policy on your insulation. If it gets wet you know it will at least keep you warm until you get somewhere to dry off.

If you are looking for a down jacket to wear in a notoriously wet situation like being on a fishing boat, working with plants, or in all weathers then hydrophobically treated down is really the only option other than synthetic fill.

When You Should Choose Untreated Down

The only reason to go out of your to avoid hydrophobic down is if you are sensitive or allergic to the chemical treatment itself. The rest of the time it doesn’t really matter unless you specifically want the maximum loft and weight-to-warmth ratio. Even then the difference is unnoticeable at first.

If you do not expect to push your down-filled equipment beyond its natural limits then there is no reason to get a hydrophobic down fill. You should instead look at the other features such as fill power and fill weight which will have a greater impact on your decision.

Also, if you take care to wear a waterproof over the top of your down jacket or use a bivy bag over your down sleeping bag then getting soaked will never be an issue.

Different Hydrophobic Down Brands

There are several different brands of hydrophobic down that all do essentially the same thing. They are treated with very similar DWR chemicals to repel water as much as possible while simultaneously minimizing its impact on the fine downy filaments.

Is hydrophobic down the same as DWR treated down? Yes, they are the same. DWR just means durable water repellant and the DWRs that are applied to down are also flexible.

Here are some of the more popular hydrophobic down brands:

Nikwax Hydrophobic Down

Nikwax Hydrophobic Down, or NHD as it is sometimes known, is one of the best and most refined water-resistant downs out there. They are specialists in waterproof treatments and have some of the most advanced R and D facilities for this specific type of down. Not only have they mastered how to effectively waterproof down but they have figured out how to do it without having barely any negative impact on the down. You can learn more about it here.

DownTek

I have heard many people say that for a business to become unbeatable it has to become the best at one thing. DownTek specializes in one thing and that is hydrophobic down. I first discovered DownTek when I was in an ALPKIT shop and saw that it was used in all their down products.

DownTek provides the treated down to other brands and does not make their own mass-market products. You can learn more about how they are moving towards a more sustainable and ethical way of sourcing and treating their down to ensure the best quality and safety controls here.

Sea-To-Summit ULTRA-DRY Down

ULTRA-DRY Down is Sea-To-Summit’s own branded hydrophobic down that they use in almost all of their down sleeping bags. It claims to retain 60% more loft and absorbs 30% less moisture than untreated down which are substantial improvements. You can check out what they have to say about it here and watch a short video to show the side-by-side comparison in a lab test.

Allied Feather HyperDry Down

Allied feather are like DownTek in that they do not make down jackets or sleeping bags, they simply supply hydrophobic down by the pound. HyperDry down is completely PFC-free and is one of the safest types of treated down to use. Companies like Black Diamond use Allied Feater HyperDry down in their alpine jackets. You can learn more about their down materials here.

Mountain Hardwear Q.Shield Down

Q.Shield Down is Mountain Hardwear’s version of hydrophobic down that made a name for itself with one of their signature jackets, the Ghost Whisperer. There is very little information out there about this treatment other than it is permanent and very effective on high-fill power down.

*Many other brands make their own treated down as well but have not created unique chemicals or processes that they wanted to trademark.

Does Hydrophobic Down Work?

Hydrophobic down does genuinely work. It isn’t just a gimmick.

If you watch the video below, you will see two interesting tests that were created to see how good hydrophobic down is. The first experiment involves both types of down being submerged in ink until the plume breaks down and becomes clumped underwater. Then a piece of both types of down is removed, dried, and put under a microscope. This showed that the untreated down absorbed a surprising amount of dye while the hydrophobic treated down hardly absorbed any.

The second test is less scientific but more realistic for real-world scenarios. It involves using an older version of the same jacket vs the updated hydrophobic down version and standing out in the rain for 30 minutes. By the end, you can visibly see the loft start to reduce on the natural; down version. You also hear them comment on how much weight was added after it became soaked.

Video Credit: Go Outdoors TV on Youtube

Is Hydrophobic Down Worth It?

What is hydrophobic down and is it worth going out of your way to seek it out? Yes if you use your down jacket or down sleeping bag every day in damp conditions or your life depends on it far from rescue. No, if you don’t live such an extreme life.

Does hydrophobic down radically affect the qualities of the down when dry? No, it does not, the difference is unnoticeable at first and then only starts to subtly affect the loft in the long run. It does help significantly when exposed to sustained rain or damp conditions.

If you are always mindful of the weather forecast and plan ahead then there is a better alternative to waterproof down…

The Better Alternative…

It is easier to keep down dry than to dry wet down.

Instead of getting hydrophobic down because you expect to get wet, you should proactively seek to get the best protection for your down. With a sleeping bag, this might mean choosing one that has a DWR treatment on the shell. With a down jacket, this might mean choosing one with an outer material like Pertex.

The way you can work to keep your down dry is by using waterproof clothing over the top of your down clothing and always using a bivvy bag with your down sleeping bag in wet conditions.

How Hydrophobic Down is Made

Most (but not all) hydrophobic down is treated at the same time as being cleaned. Before down can be used as a filling material, it undergoes gentle but rigorous cleaning to make sure the feathers are free of any parasites and debris. Then a dilute solution of water-based PFC-free chemicals is applied before the down is dried out.

To ensure that your hydrophobic down has been ethically sourced from birds that live in humane conditions and through sustainable means, look for a certification from RDS. This is a standard used around the world to guarantee that no birds have been subjected to treatments that cause pain, suffering, or stress.

Is Hydrophobic Down Safe?

The chemicals used to create hydrophobic down are completely safe and thanks to organizations like the Textile Exchange you can be sure the down is of a certain standard. Some people may find that they are sensitive to certain down products, either from the way they smell to allergic reactions.

It is never clear what exactly causes an allergic reaction to a hydrophobic down product, it may not even be the treated down and be caused by something else entirely. All I can say is that none of us at Gear Assistant has ever so much as smelt any trace of chemicals on hydrophobic down let alone experience a reaction.

Will Hydrophobic Coatings Wear Off?

Hydrophobic down coatings will never fully wear off unless you really clean them at a high temperature with some harsh chemicals. Over time, hydrophobic down can lose its loft faster than untreated down but it will continue to shed water more efficiently.

Hydrophobic down will last many years if looked after well. What makes the biggest difference to how long hydrophobic down lasts is how much you use it and how you store it when not in use. The more you use your down product the more it will lose its loft. You may even start to lose feathers through tiny holes or stitching that fails.

We hope this guide helped you to understand what is hydrophobic down. Get in touch with your questions and we will do our best to answer them.